Questionable old ways to straighten a neck with

heat

First, a caveat: I do not employ this technique anymore except in certain very rare circumstances. It's not a great way to correct a bad neck. In the absence of an effective adjustable trussrod, I prefer to plane and refret or simply replace a board to true up an errant neck. Working with wood as it is yields much better results than trying to force it where it doesn't want to be.Heat-straightening necks is predicated on one of two notions: 1) that you can heat a piece of wood to the point that it goes limp and you can clamp it while it's in a more ideal state and then let it cool that way. This is the same premise as a permanent for one's hair. Compare the diameter of a strand of hair with the diameter of a guitar neck, please. 2) that the glue joint between the board and the neck is able to be softened by heat, enabling you to slightly and accurately realign the components which share the glue joint. Good luck with this one, too. So this heating technique can theoretically make the wood itself go limp (as occurs when bending sides, for example) but this is very unlikely in necks. They're too big. While it's possible to heat wood to the point of limpness, it will most likely ruin not only the fingerboard but the finish on the back of the neck. I've seen it, it's not pretty. And it doesn't really soften the neck enough to take a twist or a bow out of it. So forget that idea—it's a bad one. The other technique is primarily about softening glue and realigning glued surfaces. It doesn't work very well for that either. Below, in this colored text, is my description of the theory of how these neck heaters can supposedly be used. Take it for what it's worth. Before electric silicon heating blankets and pads, there was this tool:

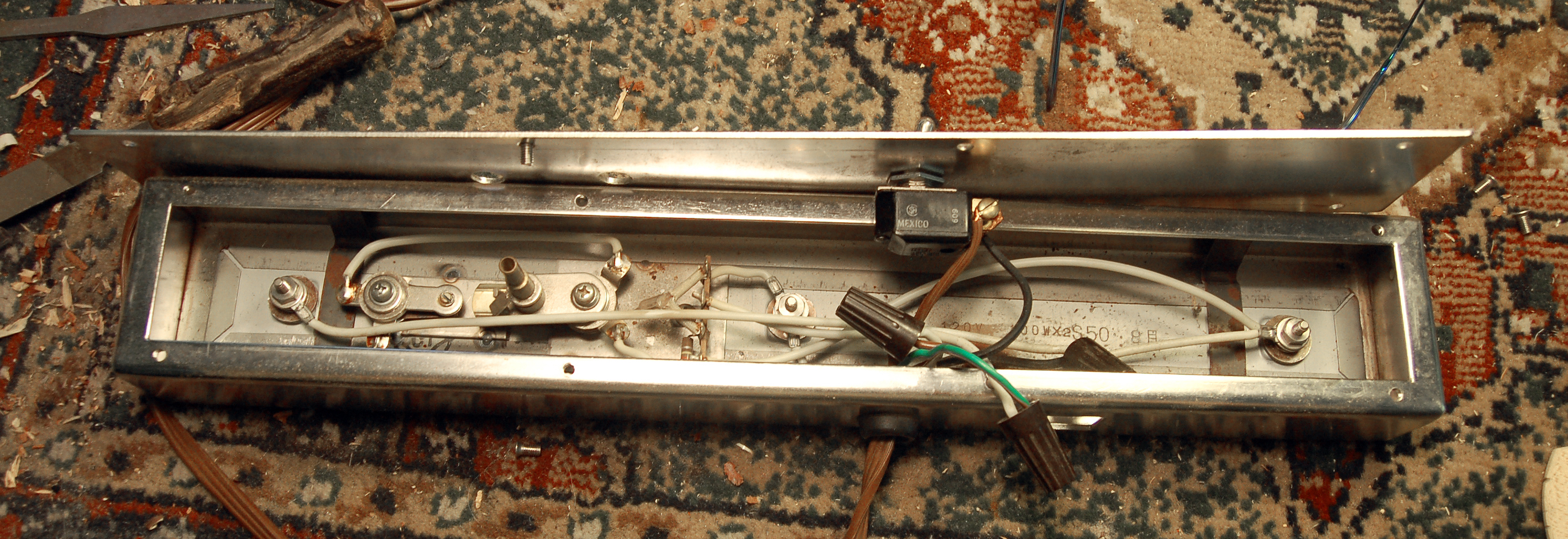

It's a very rigid steel box with a reliable true

surface, with

electric heating elements inside, and an on/off switch or a rheostat

(pictured).

Through that little hole to the right of the rheostat is a small bulb

that

tells you if it's on or not. Mine came with a pair of heavy padded

U-clamps

like the one above in the center, and another one for clamping from

through the soundhole onto the fingerboard extension.

This photo is purloined from

somewhere in cyberspace—it's not mine, but the device is just like mine was when it was new. My rheostat died almost as

soon as I got it, and ever

since, it's only had an on/off switch. If this is of any use, here's the inside of mine:

BTW, if you open this image by itself ("view image" or "open in

separate tab"), it'll be quite large. Here's "the skinny" on the voltage and watts and so on:

120V, 100 watt element times two = 200 watt item. My unit is

otherwise unmarked. The idea was to heat and soften

the glue joint between the

board

and the neck, force the neck into the desired shape under that heat and

pressure while the glue is soft, then turn it off and let it cool,

still

clamped. The glue would reset, the two surfaces that the glue bonded

would

be in a slightly different new relationship, and the neck would stay

that

way. That was the theory. In practice it took some farting around to

get

correct results. But more often than not, the warped wood remembered

where it was in the first place, and returned to that shape. In some exceptional instances, this works like a charm. Martins occasionally

work well, as do

many Asian instruments glued with epoxy. Old hide glue Gibsons and Guilds were iffy.

Older guitars of any make don't usually respond well because their hide glue

is no longer softenable. Hide glue changes over time. Water-based glues

in general do best if they still

contain a bit of water, or if the wood around them does. These devices will

make crispy critters out of any plastic fingerboard inlays, too. Very

fragrant, and very sad when you take the heater off and see what you've

done. And in efforts to get old glue joints to soften give, I have left

this 200W device on long enough to really cook the fingerboard—to the

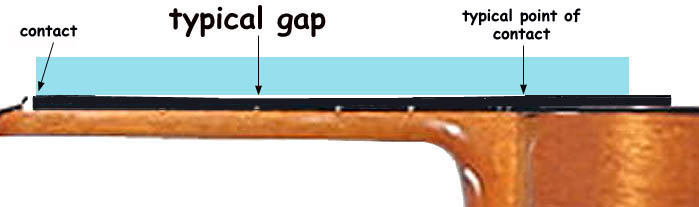

limits of actual damage—without ever having the glue budge. Here's a crude sketch of the heater (light blue thing) in full idealized contact.

In fact, the real thing is shorter than most boards, but long

enough. See the first photo above. Closer up, here:

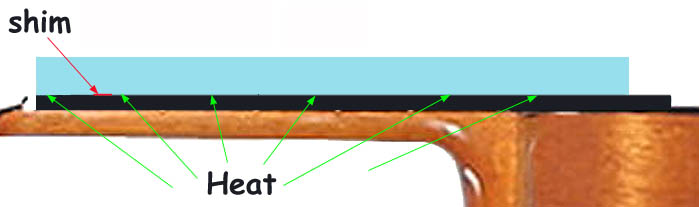

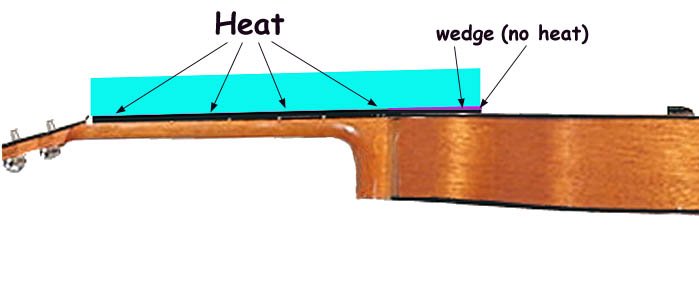

The heating box is dead true, so that when you rest it on the frets, it serves as a straightedge. Thus, before you do anything, you can see the expected gap, which if all was going as planned, you would believe it could fix. But simply clamping the neck flat to the heater alone is usually insufficient. Instead, I put a small shim (such as a piece of cardboard) between the heater and the first fret, to overbend the neck a bit. After the whole thing cooled and the clamps come off, there will be a bit of springback, and the desired relief will, one hopes, be there.

This takes care of the most common problems. A twist can allegedly be

dealt with

by strategic use of shims in various places. A lot about this tool

involves

trial-and-error. And a willingness to punt and use other methods. Again—I recommend planing and refretting.

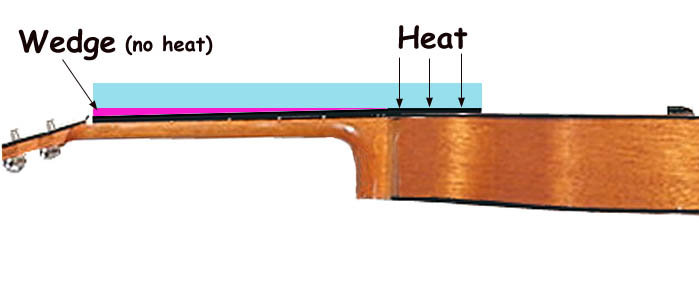

The shape of the wedge is, of course, exaggerated for this illustration. The actual one I've used for years is made of pine. In this procedure, the fingerboard extension moves ever so slightly back from the soundhole. No touchup is required, but it moves enough to re-angle the neck a bit.

Sometimes, when dealing with a typical bowed neck, I'll put a shim under the fingerboard extension to push the neck back as it heats the misshapen part of the neck (below). This is a lighter "reset" yet, but in rare instances of success, it can save the day with guitars with borderline reset issues. The heating device is extremely strong and rigid, so you can clamp like mad and it will stay straight. This gives it a distinct advantage over silicone blankets and so on.

In short, the steps above were thought to work, but only

actually worked 10% of the time, at best. All I really use this for

anymore is for softening glue underneath a board to aid in removing it. I

also used to use it to heat just the the end of a fingerboard where it lay on the top of the guitar, as part of preparing for a neck reset.

However, I made a similar thing for this task from a

huge oilite bronze

roller bearing many years ago.The bronze bearing I use was sliced down

the center and

has a porcelain handle on it. I heat it on a hotplate, and use it to

soften

the glue under the end of the fingerboard when I'm preparing to remove a

neck

for a reset. Again, I prefer to keep the heater off raw wood, as it

will scorch it; the frets are a good spacer. So I'm not a sales

prospect for the thing

above. But it's potentially a good idea for a specific task, and I

invite you to try something like it. Please don't ask me to do this

work! Again, there are old hide glues that are simply not affected by heat (anything by Lyon and Healy comes to mind). But when all you want to do is get the old board off, even ancient glue joints can be coaxed into yielding with a little help from the heat. I hear of other people getting amazing results on older

instruments with these neck heaters.

I tend to see their "amazing results" showing up in my shop a few years

later after the

neck wood magically remembered where it had been before. I don't think they're a Big

Answer tool, and most people I know who used them starting back in the

early '70s have moved on to other much better methods of straightening necks, as I have.

But they're an interesting tool and serve an occasional purpose. If I

lost mine I'd make something similar using silicone heating blankets.

* Back around 1972, a local music distributor had a batch of about 500 copies of a Martin 000-42 made in Japan. All had the same cluster of production flaws which rendered each and every one of them utterly unplayable and unsalable: bowed and unadjustable necks, and ill-considered neck angles. Lucky me, I got the gig to straighten all 500 necks, shave the bridges, and set them up to play well. I don’t remember the brand—Tama perhaps?—but I think it was either Coast or Sahlein that imported them and dumped the gig on me. It paid my rent for a couple of months, and I got real fast at doing this procedure! In any case it was a very long time ago. They either had that tool made for the job, or somehow landed one, and gave it to me to do the job. I rarely used the neck heater anyway. Music Is A Service Industry!

|

Drop

me

a line or something:

Drop

me

a line or something: