and C.F. Martin bought 'em to put on their fancy guitars:

They even had their name stamped on the plates.

At first glance they look nice. 15:1 which is slightly overkill. They turn smoothly if they're still in one piece.

These should have worked, because Gotoh has long made very good quality gears. No one is a bigger partisan for their products than I am. Somehow over the last year or two, their engineering department has defied common sense by coming up with some rather questionable items, including these gears that are complicated and oddly thought out. When they fall apart, there is nothing to do but throw them out and replace them.

Gears are not supposed to have so many unnecessary little plastic parts.

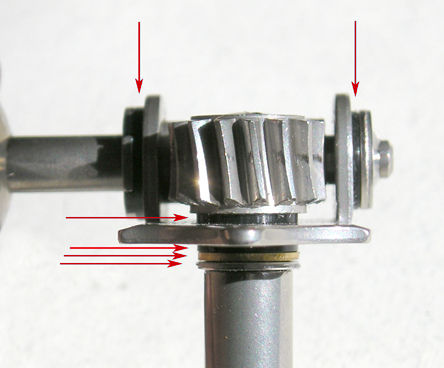

Here's the Achilles Heel.

It's the black plastic toothed bearing washer between the flange on the button shaft and the end bushing tab. (This particular one's still intact and working OK.)

Whatever it is made of, it's not good enough, because these are coming direct from Nazareth in shreds. I've had a total of 9 dead ones so far.

There are little washers all over this gear.

Why?

You will notice six washers here.

Four are plastic, one is brass and one is steel.

This is six more washers than any gear should really need.

Gotoh had precision machining down a long time ago, and their gears worked beautifully without all this.

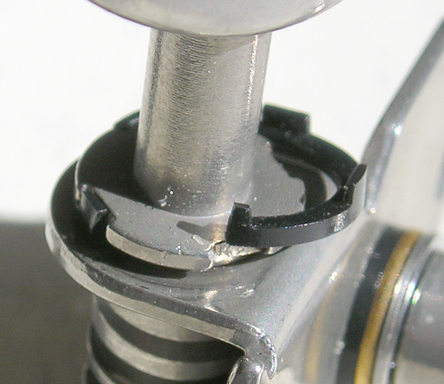

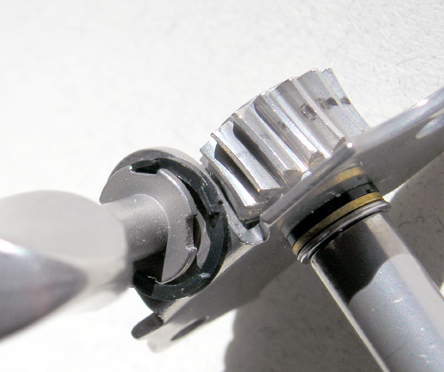

Split bearing washer = instant expensive junk. With this washer gone, the gear just flops around. You can't tune or play the guitar.

Two of the six machines on a brand new D-18 "1937 Authentic" were like this when the case was opened from the factory. They are now in my parts pile and have been replaced with a set of Waverly 4060s, which are also arguably a little more complicated than they need to be but have a proven track record as a quality gear. And fortunately they drop right in with no installation issues.

A few more shots of why a brand-new and very expensive guitar couldn't even be tuned up:

It's assembled with a pressed-on retainer clip that can't be removed and put back on. It's a one-time installation when the gear is assembled.

Why would anyone make a gear that has born-to-fail parts that can't be fixed or replaced?

And even if replacement parts were available, why would anyone want a gear so unnecessarily over-engineered and so fragile?

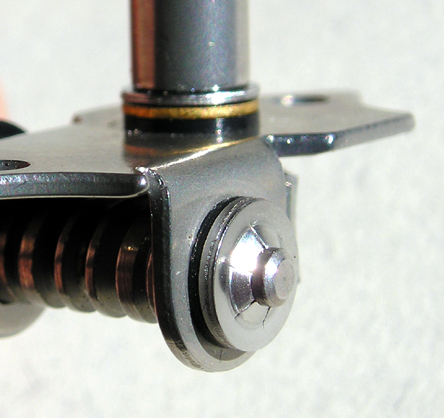

Nit-picking Dep't.

While we're picking on poor old Gotoh, I also wonder why would they go to the trouble of having a nice vintage-looking slotted tension screw in the cog, and then supply the gears with cheesy Phillips-head screws to attach them to the guitar?

If you're going to the trouble of generating a vintage look, why not supply vintage screws?

Cost?

Convenience?

Nah.

Ordinarily you install gears once and never think about it ever again.

I feel worse about C.F. Martin and their hapless customers because these oopses are going to cost them a lot.

Gotoh came up with a revision of their good mandolin gears in 2006 that is also problematic. They had such a good thing going for so long and then they changed their mandolin gears for (in my estimation) the worse. None of the improvements were improvements. They don't turn as well as the earlier ones did, and unless you're willing and able to reshape their button shafts, they don't accept anyone else's after-market buttons anymore. Click here to jump to a page with information on that.

Again, I have always been—and remain—a staunch believer in Gotoh products. I can only hope that they learn from this and put out better-designed versions and swap them to their poor customers. But simply contacting Gotoh is nearly impossible. A few suppliers in the US carry limited offerings from Gotoh's product line, and they can't deal with problems like these, or even order other things from the larger line.

Curious.

Questions? Have more info? Please

drop

me

a line by

clicking

here